Design of a platform based on arrays of high resolution quartz sensors for HTS (High-Throughput Screening) of residues in honeys

The main objective of the project is the design, implementation and experimental evaluation of a technologic demonstrator based on arrays of high resolution quartz microbalance sensors for High-Throughput Screening (HTS) applications in the detection of pesticides and antibiotics residues in honey. The control of chemical residues is essential in honey’s marketing to ensure consumer safety. Currently, this task is not completely solved. Although there are some equipments based on analytical techniques which reach the limit of detection (LOD) required, this is the case of techniques based on liquid cromatography (HPLC), they have certain drawbacks that make them not suitable for an in-situ implantation in packaging industry honeys. They are high cost and time consuming techniques which require highly qualified staff. There are other solutions on the market which, although are faster and do not need quialified staff, do not reach the required LODs. Therefore, exists the necessity of proposing other faster, simpler and low cost alternative techniques which reach the required LODs. This necessity identified in the sector of honey packaging industries fits perfectly with challenge, «Safety, food quality, sustainable and productive farming, sustainability of natural resources, marine and maritime research» established in the national research lines. The proposed technology has been previously used and tested in the detection of pesticides in water and fruit juices. For these applications the technique fulfilled the requirements of sensitiviy, selectivity, easy to use and low cost. Sensitivity and selectivity requirements are achieved by using an inmunosensors based on the recognition antigen-antibody. Nevertheless, one of the challenges that remains unsolved in this technology is its ability to detect a large number of compounds simultaneously. By solving this challenge, a great amount of time will be saved in an application such as the one proposed in this project. This is the main challenge to be solved with this project. The demostrator will be tested in the simulataneous detection of 3 antibiotics and 2 pesticides from the organophosphates and organochlorines families. The resulting demonstrator, will be the first step for the design of a prototype that can be used in honey packaging insdustry. Technological transfer of the results achieved with this project would cover the existing deficiency in the companies of this sector, who need simple, fast and reliable techniques which reach the requiered LODs.

It is important to mention that the developed demonstrator could also be adapted to other application fields included in the challenges of this call, such in the case of pollutants in marine waters, where there is also the necessity of technological solutions as the one intended to develop in this project.

- Result 1: An immunosensor HFF-QCM has been developed that allows the quantification of residues of the pesticide Carbaryl in honey below the levels established by the current European legislation (MRL = 50 ppb). The results obtained in the project show that the measurement technique based on immunosensors HFFQCM is very accurate, but not very precise. In this way, the accuracy values required by SANCO standard are achieved, but not the precision ones. Therefore, it is established as a challenge to improve the precision of this technique.

- Result 2: The results obtained in the project show that the HFF-QCM technology can be considered a serious alternative to the quantification techniques of current honey pesticides, since it reaches detection and quantification limits close to those achieved by gas chromatography (LC-MS / MS), but without the need for a complex pretreatment of the sample.

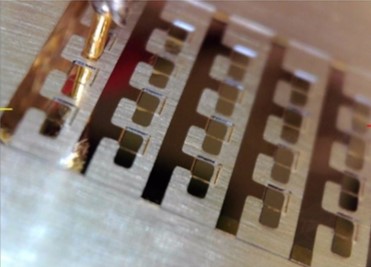

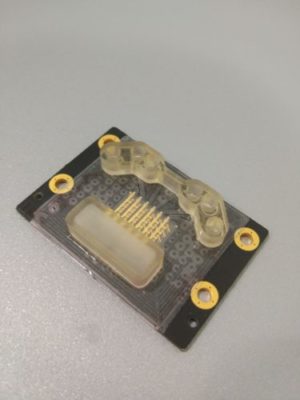

- Result 3: A cartridge based on HFF-QCM sensors has been designed and manufactured for High-Throughput Screening (HTS) applications in the detection of antibiotic residues and pesticides in honey. The cartridge is composed of three elements: an array of 24 HFF-QCM sensors, a contact PCB and a microfluidic layer. Several experimental assemblies that facilitate the fabrication of the prototypes, as well as their testing and evaluation, have been defined and developed. Finally, characterization measurements of admittance spectra, and scattering parameters were performed for the different prototypes of the different cartridge fabrication process.

- Current work lines: Currently, the designed cartridge and immunosensor are being tested. At the same time, we are working in the development of an immunosensor for the detection of antibiotics: tetracyclines and sulfonamides.